In the middle of Big Spring, Texas, a new name is making waves in the damp frac sand industry. West Point Silica, founded in 2023, has quickly grown into a key player in the production of damp frac sand, a dust-reducing alternative to traditional dry frac sand. Co-owned by Sterling Miller, the company’s rise in such a short time is a testament to a simple formula, produce a high-quality product, invest in Terex Washing Systems equipment, and partner with people who understand the urgency and precision that the industry demands, which happens to be Powerscreen Texas.

West Point Silica (WPS) mines raw sand directly from the ground, then washes, sizes, and prepares the sand for sale. Their main product is 100 mesh damp frac sand, which they sell across the Permian Basin, one of the most active oil and gas regions in the country. By focusing on a single, consistent cut and offering it in damp form, West Point Silica eliminates one of the biggest issues plaguing the industry, airborne dust. This not only helps meet environmental and workplace safety standards but has also made their product a sought-after solution among customers looking for cleaner, more efficient sand handling.

Built on Quality and Speed

When West Point Silica first started, their setup included a Terex Washing Systems M2100 wash plant. But as their demand quickly grew, they needed equipment that could produce more on a larger scale. It wasn’t long before they made the switch to the AggreSand 206, acquiring not one, but two units through Powerscreen Texas. This decision marked a turning point in their production capabilities. The AggreSand 206 wash plants offer a much larger screen deck and a more efficient layout, eliminating the need for traditional wire screens and pushing throughput averages up to 200 tons per hour per plant. That volume is critical, not only to meet their current commitments but also to provide a buffer that ensures they can keep up pace with future demand.

Additionally, WPS purchased a Terex Washing Systems FM 200 C-2G sand processor that is responsible for bringing their damp frac sand into spec with the use of its centrifugal force within the cyclones to remove clay, silt, and slime that may be in the raw material. Featuring a collection tank, slurry pumps, hydro cyclones, and a dewatering screen all in one compact unit.

For Sterling, one of the most enjoyable aspects of working with the AggreSand 206s has been learning how to fine tune the system. “Finding the sweet spot on these machines has been a favorite part of the job,” he shared. “Dialing in the settings, adjusting the speed rates, figuring out how each component reacts, it’s been a great process to understand what it takes to consistently produce exactly what our customers are looking for.”

That hands-on learning has extended to the entire crew. Sterling praised how quickly his team was able to acclimate to the new machines after receiving training from the Powerscreen Texas team. “Once everyone was trained, it was easy for them to manage the plants. The design and functionality of the AggreSands make them incredibly operator-friendly.”

Partnership That Keeps Production Moving

Despite doing much of the routine maintenance in-house, West Point Silica maintains a close working relationship with Powerscreen Texas for service and parts. In an industry where downtime can quickly lead to missed deadlines and lost revenue, having responsive support is non-negotiable. “It’s crucial to have a partner like Powerscreen Texas,” Sterling explained. “They understand how important uptime is in this business, and they act with urgency. Whether it’s a part we need or a service call, they’re always ready to get us back up and running fast.”

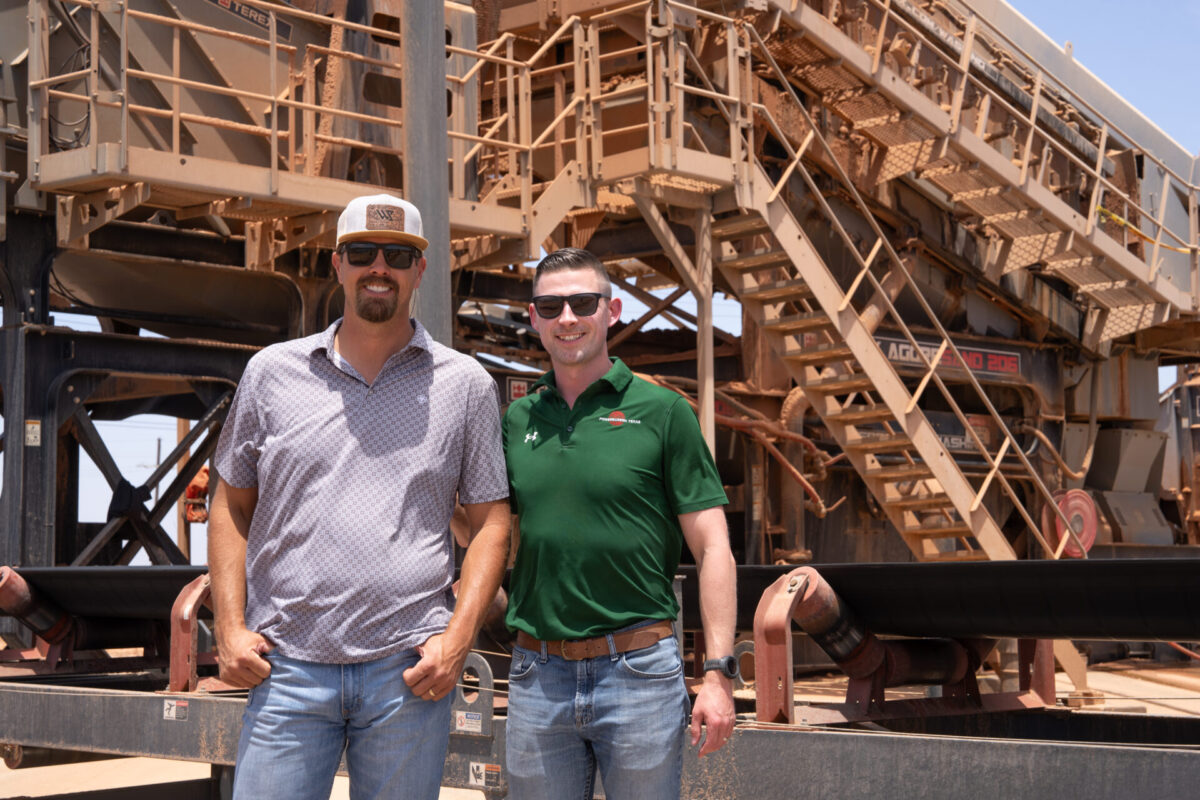

A major part of that partnership has been Sterling’s long-standing relationship with Stephen Devane, Sales Representative at Powerscreen Texas. “Stephen has been a great partner. I’ve known him since 2017, back when I was just getting started in mining,” Sterling said. “He’s been a huge asset to our operation. He’s helped us navigate equipment decisions, answered countless questions, and has always been there when we’ve needed guidance.”

Dialed In for Precision

The AggreSand 206’s design offers significant operational advantages. Though it’s a readily portable unit, its compact footprint and pre-wired components make setup feel more like a static plant. That combination of mobility and stability allows for quick installation without major site prep, something Sterling greatly values given the pace at which they’ve scaled. The minimal installation time and flexibility have allowed them to deploy multiple wash plants on site without any impact on production.

Looking back on their growth since opening, Sterling attributes much of their success to the quality of their finished product. “The consistency and cleanliness of the sand we’re able to produce with these wash plants has been a game changer,” he said. “Our customers expect a top-tier product, and thanks to the TWS equipment, we’re able to deliver just that.”

As West Point Silica continues to scale in both volume and reputation, their focus remains clear, deliver a clean, consistent, high-quality product that meets the evolving needs of the Permian Basin. With a hands-on team, a clear product strategy, and strong partnerships with companies like Powerscreen Texas, they’ve built a foundation for long-term success, one load of sand at a time.